Baratrons & Valves

All pressure devices are calibrated on automated MKS Vacuum Diagnostic Systems. These systems allow our technicians to test from 10 Mtorr to 5000 Torr within +/- .08 % of reading accuracy. Laminar provides a complete service, including sensor and PCB replacement as needed. Re-ranging service for all manometers as well as calibration of pressure controllers and pressure devices is available.

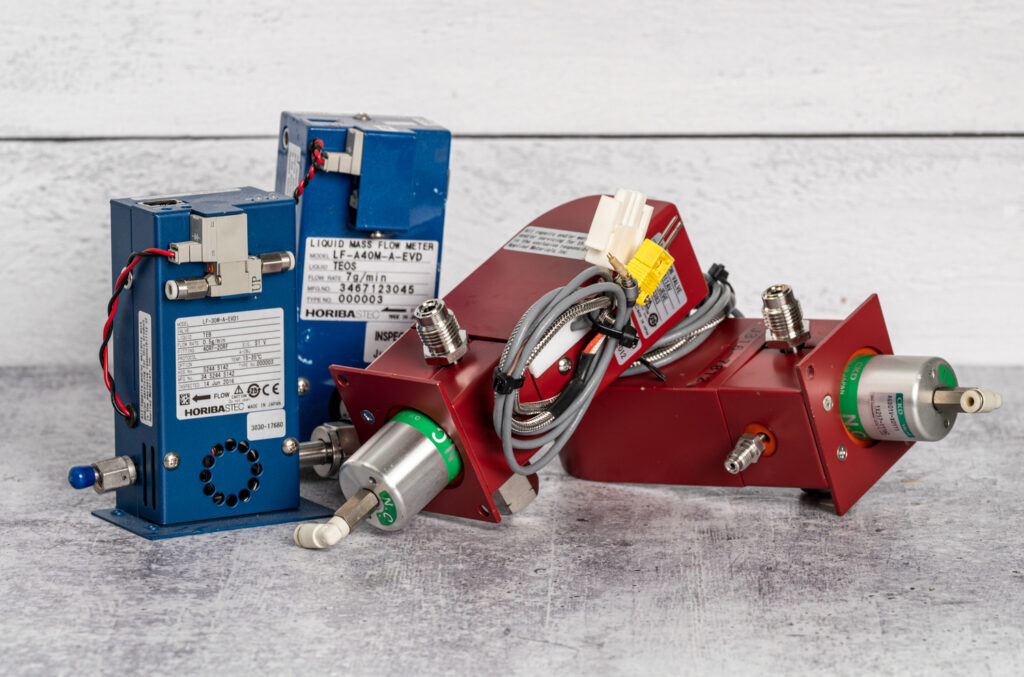

Our exacting rebuild process starts with the dismantling of each valve, which is subsequently cleaned and inspected. Using a proprietary system purpose built for testing valve functions, Laminar analyzes motor function, checks valve positioning, validates leak integrity and tests flapper assembly functions on every valve.

Based upon test results each valve is rebuilt as needed to conform to manufacturer’s specifications. A new seal and bearing kit is installed in every valve and Teflon re-coating is applied as needed. Just prior to packaging, a three phase quality assurance test represents the final phase of our rebuilding process.